What is it?

What is it?

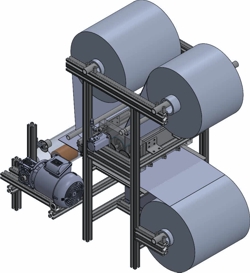

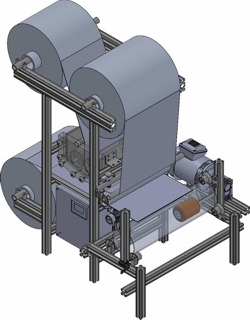

The driven shear impregnator is an experimental power-assisted system, which can fit into a conventional solvent-based treater, but provide better wetout than is currently attainable.

Improved wetout means new products with higher fiber content and more viscous resin will become a reality as well as faster, more-efficient production of existing products. For practical reasons, though, because it is small, the driven shear impregnator can be installed into an existing line while still permitting the production of existing prepregs without changes.

The driven shear impregnator is designed with normal production requirements in mind. It can be quickly disassembled and reassembled for cleanup and servicing, and it can be set up to make a range of products. The pilot unit will be ready for trials very soon, and we are looking applications where its extra power will make a difference. The principle is simple, but it has not been done yet, and results of previous methods do not apply.

How does it work?

How does it work?

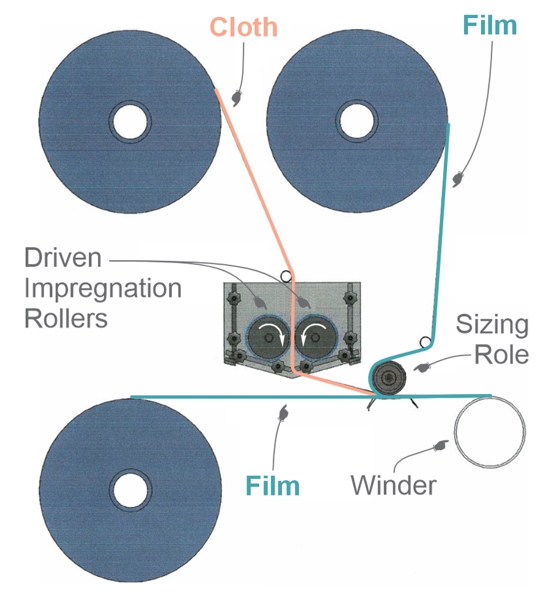

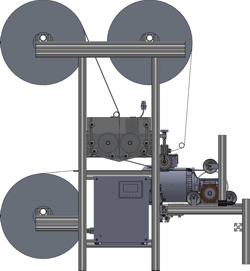

Two horizontal driven rotating rollers are mounted in a resin bath with a small gap between them. The fiber mat is fed into the resin between the rollers and it passes through another gap directly below the line between the rollers. With minimal clearance between the rollers and the bottom of the tank, pressure is built up in the volume between the rollers where the cloth passes. This increased pressure between the rollers pushes resin into the fibers, and it forms a barrier to entrained air that keeps it out of the product as it passes through.

In the pilot line, after the resin-impregnated cloth passes through the bottom gap, film is introduced above and below the product, and the product is sized and then wound on a core.

The sizing station in this unit is adjustable and made so that the operator can determine whether the product is in tolerance as the line operates. The operator can adjust the speed of the impregnation rollers during operation to keep the product in range. The winder sets the speed for the line. These features are incorporated to make a stand-alone unit, but they could be replaced by features of an existing line that perform equivalent functions.

What’s new about it?

Existing lines operate only at line speed, but here the impregnation rollers can rotate much faster than line speed. That’s why there is higher pressure in the resin that the cloth passes through. This pressure comes from the shearing action of the rollers on the resin. As such, it will only work with viscous resins, which are a target of this system. In existing lines where solvent is added only to make the resin thin enough to wet out, the extra solvent could be reduced or eliminated by this system.

Existing lines operate only at line speed, but here the impregnation rollers can rotate much faster than line speed. That’s why there is higher pressure in the resin that the cloth passes through. This pressure comes from the shearing action of the rollers on the resin. As such, it will only work with viscous resins, which are a target of this system. In existing lines where solvent is added only to make the resin thin enough to wet out, the extra solvent could be reduced or eliminated by this system.

We believe we have a production-worthy system that can be used to make new products or old ones more economically. It is not meant to replace existing equipment which is used successfully where there is no need for improvement.

We believe we have a production-worthy system that can be used to make new products or old ones more economically. It is not meant to replace existing equipment which is used successfully where there is no need for improvement.