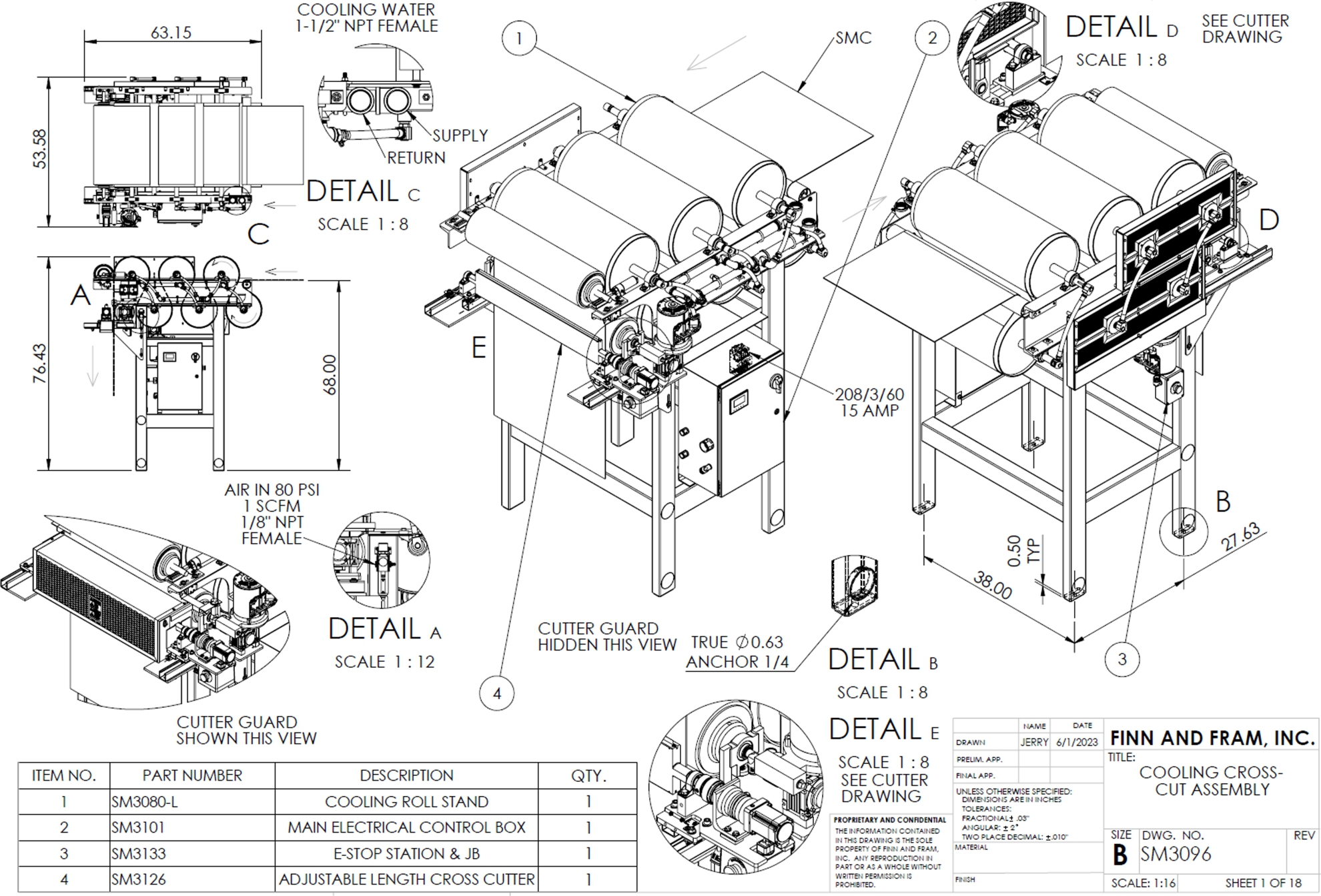

The Finn and Fram cross cutter is a simple and reliable way of making straight cross cuts of adjustable length on fiberglass mat, carbon mat, SMC or prepreg in a production line. It has a small footprint, and it makes its cuts as the product moves without requiring any pause or accumulation of material.

The Finn and Fram cross cutter is a simple and reliable way of making straight cross cuts of adjustable length on fiberglass mat, carbon mat, SMC or prepreg in a production line. It has a small footprint, and it makes its cuts as the product moves without requiring any pause or accumulation of material.

The Finn and Fram cross cutter functions like a standard fiberglass cutter with blades pressing the material against an elastomeric anvil roll and parting it. Like a standard fiberglass cutter, the action is better for cutting brittle fibers like fiberglass or carbon than it is for softer fibers, which do not break.

With brittle fibers, the blades and rubber sleeve last a very long time with minimal servicing. However, in cutting SMC or prepreg carried by a plastic film, the cutter will part the material and also make a score cut in the film that can be pulled apart to complete the cut, and the blades will last a long time in that mode.

With brittle fibers, the blades and rubber sleeve last a very long time with minimal servicing. However, in cutting SMC or prepreg carried by a plastic film, the cutter will part the material and also make a score cut in the film that can be pulled apart to complete the cut, and the blades will last a long time in that mode.

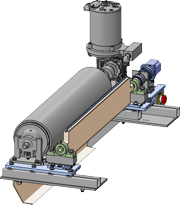

The cross cutter differs from a standard cutter in that the body of the cutting head does not contact the anvil roll, so the two rolls do not rotate together. Instead, the cutting head is driven separately by a servo motor that controls the cutting head travel to achieve the desired cut length while assuring the two rolls go the same speed when in contact for the cuts. The blades are mounted on a bar and contact the anvil roll only when they make cuts. Between the cuts there is space for the mat or SMC to travel at its own speed.

Depending on the application, the Finn and Fram cross cutter can be mounted with heating or cooling rolls, slitters, or film strippers or other equipment as required. The cut length can be set after each cut permitting closed-loop control of the cuts or cutting patterns.